Super large chord rod profile intelligent welding and assembly factory

Contact Us

Classification

Product Description

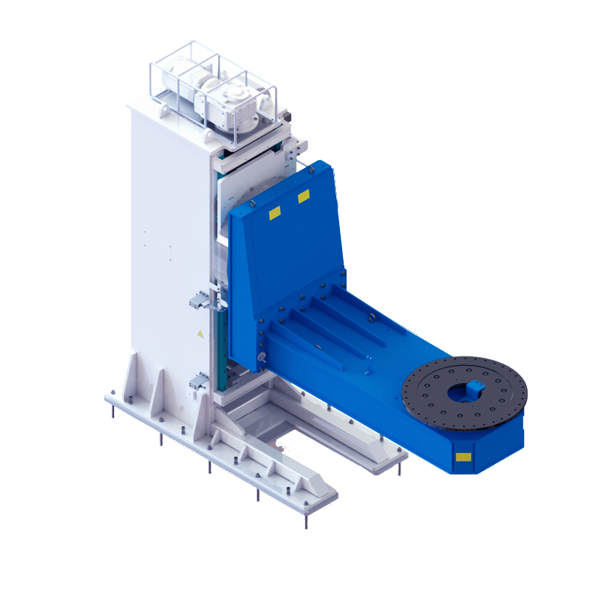

The production line consists of H-beam assembly stations, angle steel assembly fixtures, robotic automatic welding stations, and dust removal systems, suitable for the automatic welding of structural components such as super-large tower crane truss main chord H-beams and angle steel assemblies.

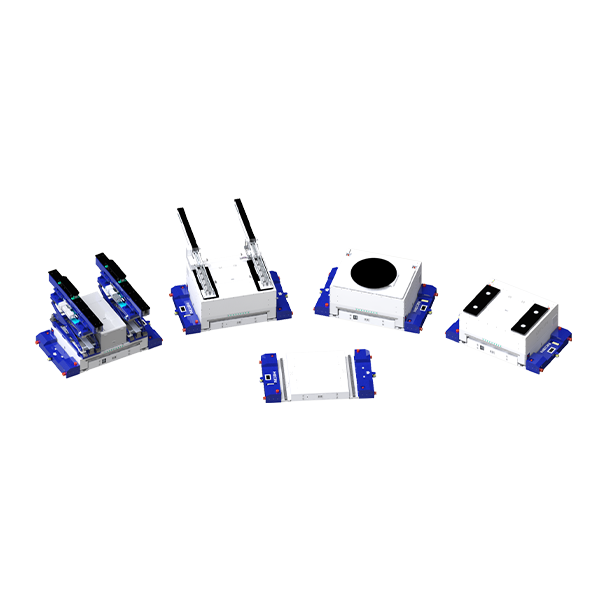

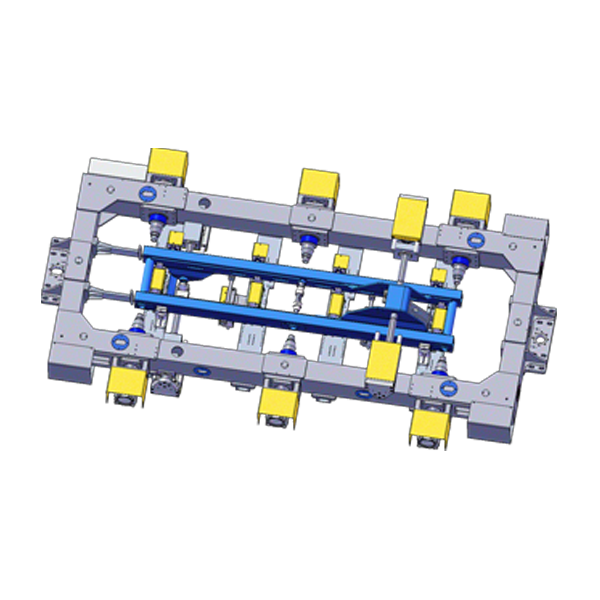

(1) The H-beam assembly station is mainly used for H-beam assembly, spot welding, and reverse deformation tooling.

(2) The angle steel assembly fixture is used for manual assembly, spot welding, and root welding of angle steel assemblies, and it automatically welds along with the workpiece.

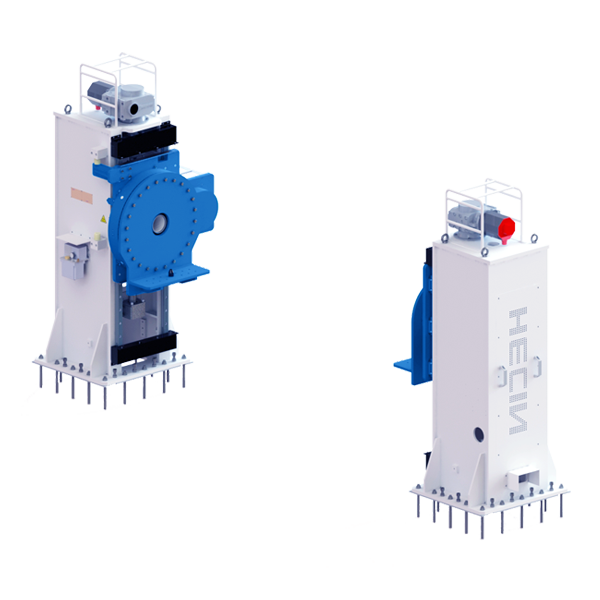

(3) The automatic welding station is mainly used for automatic preheating and automatic welding of H-beams and angle steel assemblies.

Technical Highlights:

The super-large chord breaks through the traditional root cleaning process for H-beams, with super-thick plates requiring no root cleaning and achieving full penetration, resulting in an unmanned intelligent welding process throughout production.

From the assembly station to the full welding station, material flow reduces labor costs and improves production efficiency.