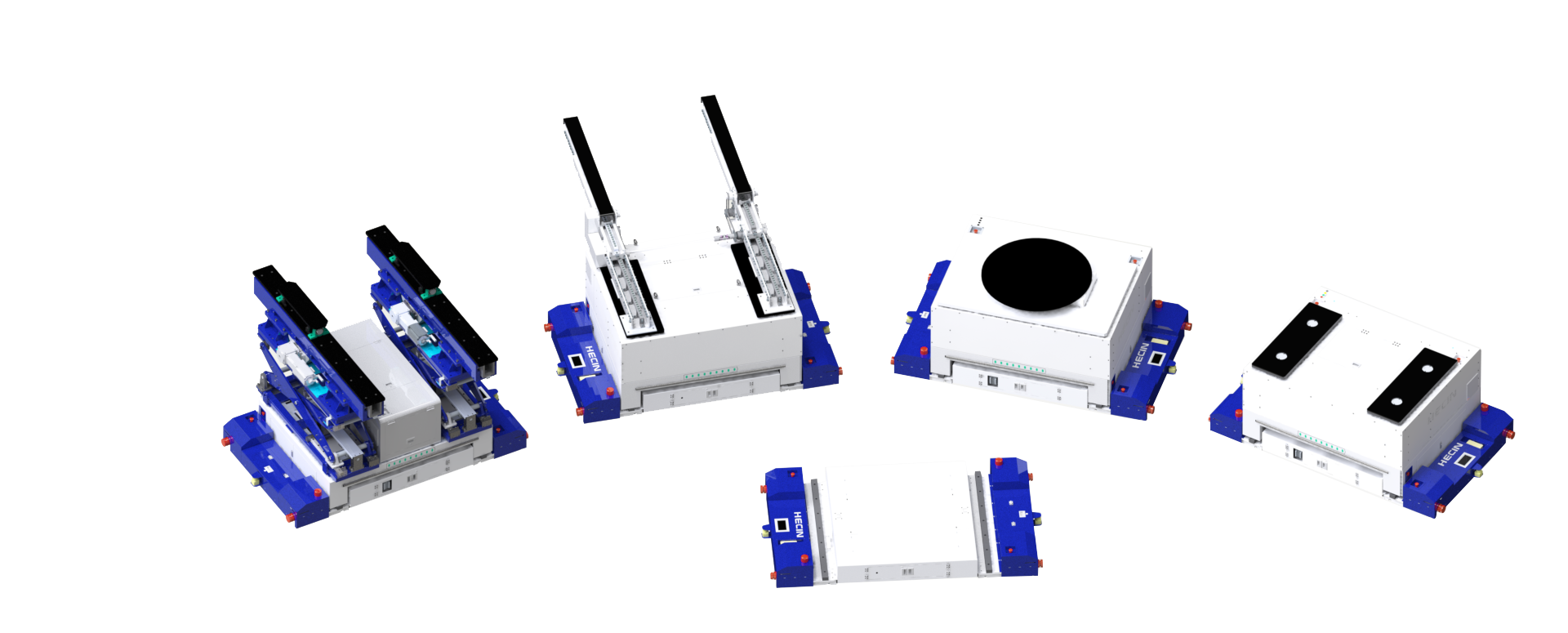

Intelligent Logistics Robot

Contact Us

Classification

Product Description

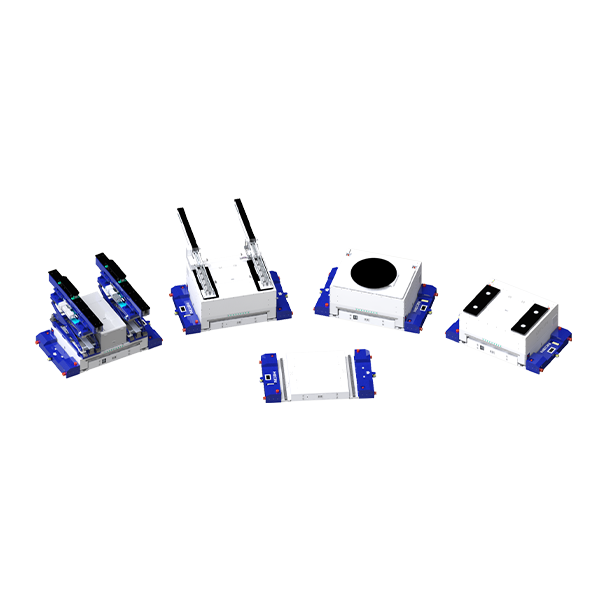

Intelligent Logistics Robot - Heavy-duty RGV:

Structural Design

Minimum 130mm ultra-low chassis design, enabling quick track laying, reducing foundation standards, with a maximum load capacity of 50 tons; composite design of mother-child vehicles or single four-section vehicle body; independent design of functions required for transportation, achieving modular combination.

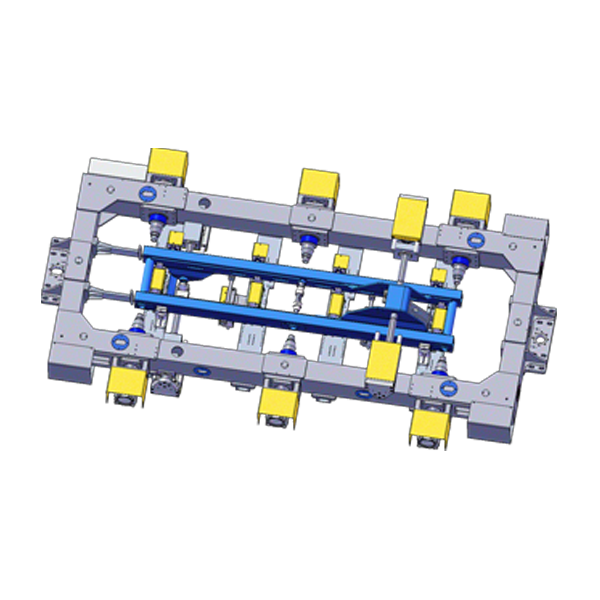

Drive Positioning

Using DC servo dual-drive or four-wheel motor, the vehicle starts and stops smoothly without shaking, solving wheel slip issues through an intelligent power system, with strong power and stable operation.

Energy Control

Equipped with an intelligent battery management system with IC+TI energy management chip, combined with a modular lithium iron phosphate battery pack with intelligent insulation and heat dissipation system, meeting long-lasting use under different working conditions.

Control System

Using a self-developed ARM architecture embedded control system, achieving precise control of logistics robots, precise positioning of the vehicle body through QR codes, and high-quality communication between multiple RGVs via WiFi network.

Safety System

The RGV robot is equipped with an intelligent lighting system and laser radar, achieving visual safety feedback and intelligent obstacle avoidance functions under different conditions.

Scheduling System

The self-developed RCS scheduling system enables online editing of workstation maps without complex on-site programming; it achieves optimal path planning for multiple robots, optimal sorting of production orders, rapid task deployment, and automatic generation of logistics trajectories; rapid deployment and docking of logistics robots with sensors, robots, PLC systems, and manual calling systems through address codes.

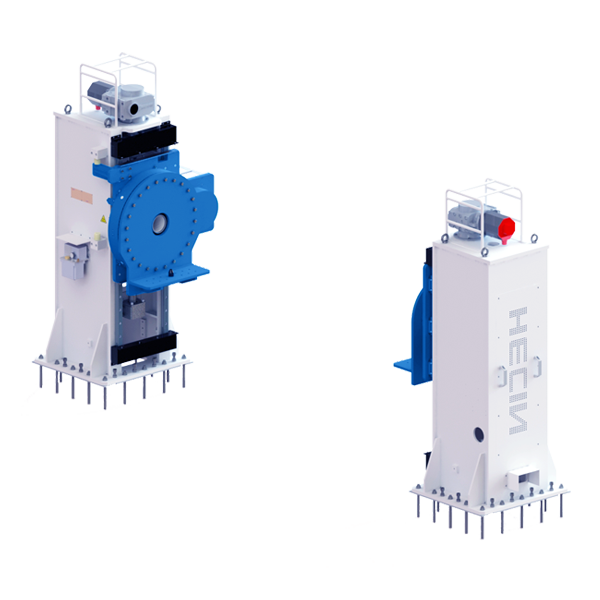

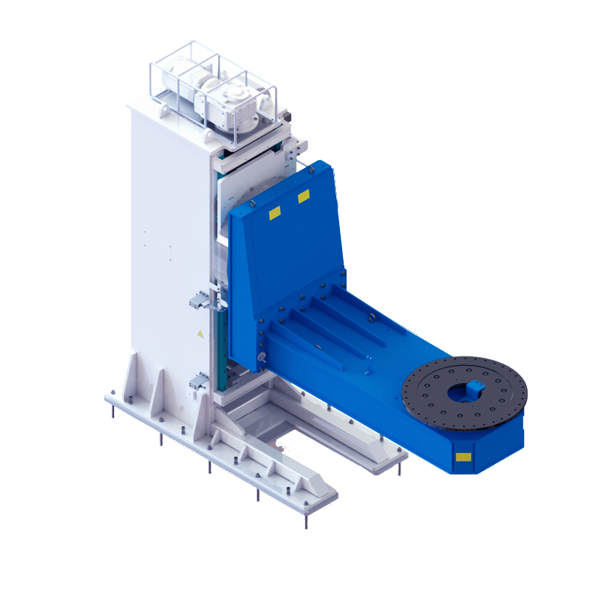

RCS System:

In response to the flexible needs of automated production lines, Hexin Group has independently developed an intelligent RGV mother-child vehicle powered by batteries and laser QR code navigation; equipped with the self-developed RCS system, it can achieve automatic production scheduling, long-distance precise positioning, continuous stable operation, low cost, multifunctionality, and automatic obstacle avoidance.

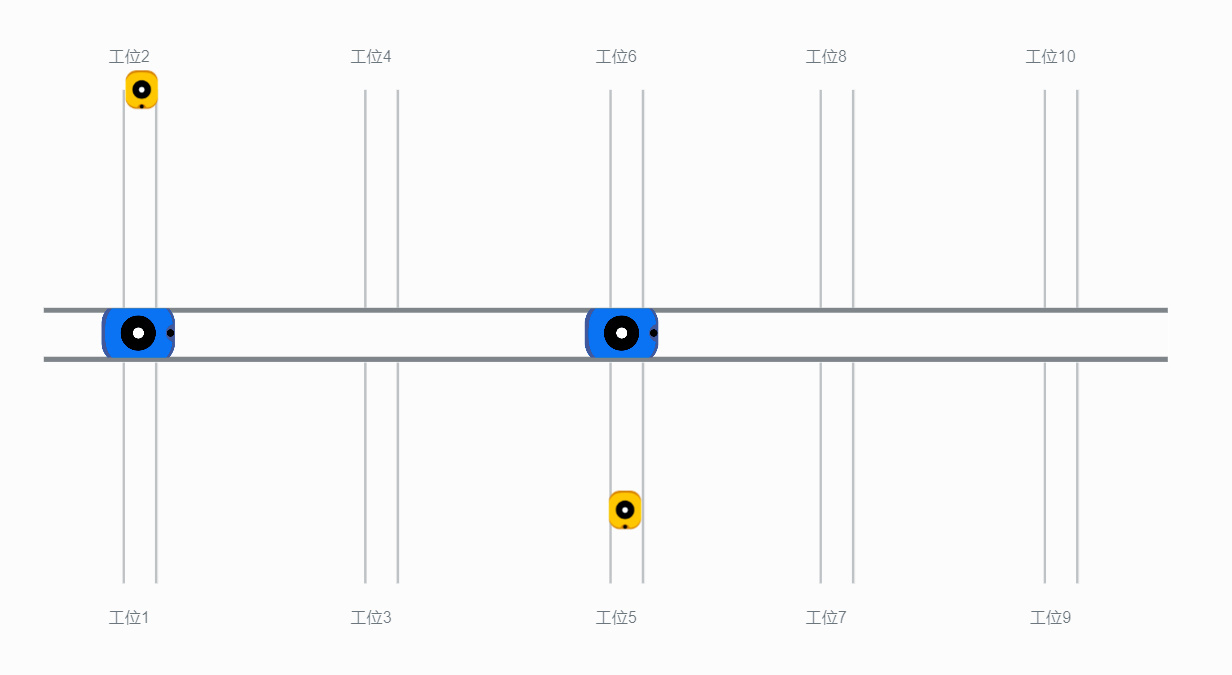

Task Generation:Set the driving tasks for the small vehicle, divided into demonstration tasks and automatic tasks, where demonstration tasks are used for vehicle simulation.

Map Information:Set the movement track of the small vehicle, divided into main tracks and sub-tracks, for RGV small vehicle simulation.

Map Simulation:The RGV small vehicle performs movement demonstrations according to the set map and tasks.