HECIN Central Control System

Contact Us

Classification

Product Description

Commentary Video

HeXin Central Control System

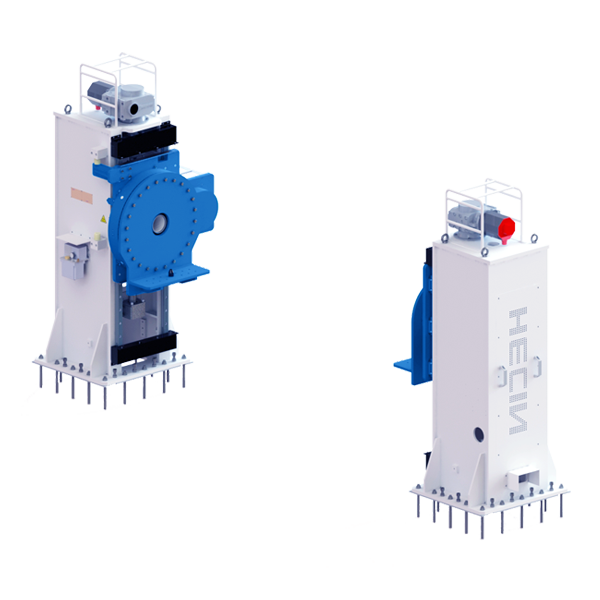

The 'Hand' of the Smart Factory:

By using the intelligent control system, various equipment communication protocols such as robots, CNC machine tools, digital welding machines, and programmable logic controllers (PLC) are integrated to enable unmanned production.

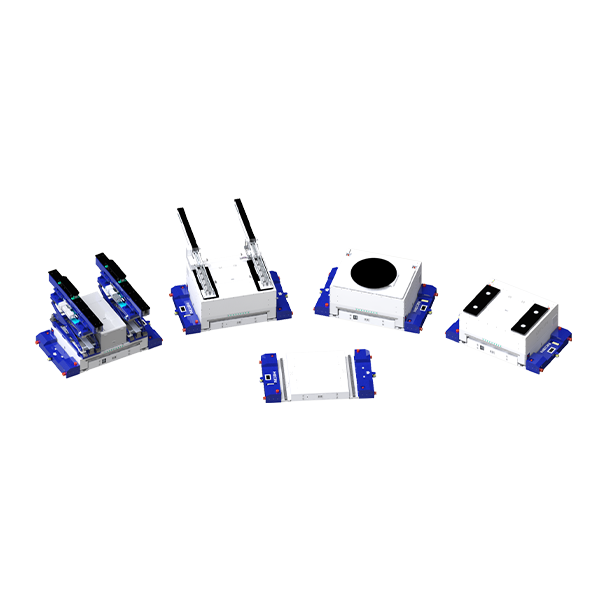

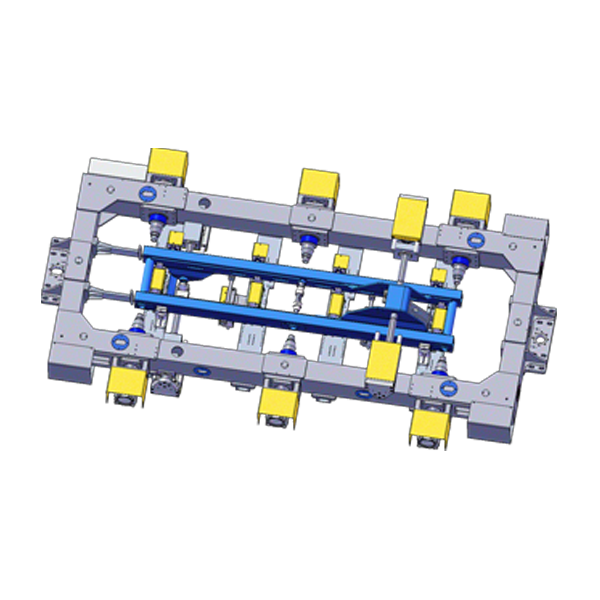

The 'Foot' of the Smart Factory:

By using self-developed aerial robots, workpiece positioning mechanisms, heavy-duty logistics robots, and in-plant inspection robots, manual intervention is reduced, allowing materials to flow freely within the factory.

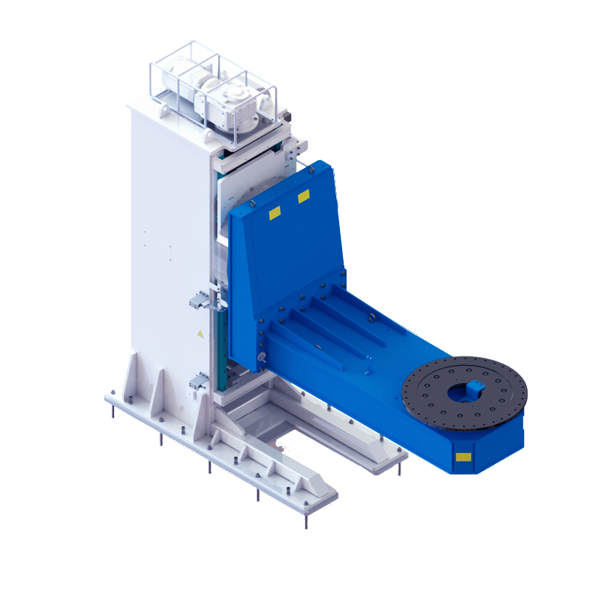

The 'Body' of the Smart Factory:

By forming a network assembly control through wired, WIFI, or 5G, combined with self-developed edge computing devices for data collection and analysis from equipment and production lines, production plans are arranged based on the data.

The 'Eye' of the Smart Factory:

By integrating various sensors with laser measurement, 3D vision, radio frequency identification (RFID), and industrial QR codes, various devices can 'see' each other.

The 'Brain' of Intelligence:

By using self-developed IMS system (a general network architecture that provides multimedia services based on IP networks), welding parameter programming systems, quality online detection systems, and other software-driven solutions, overall control and command of the production line is achieved.