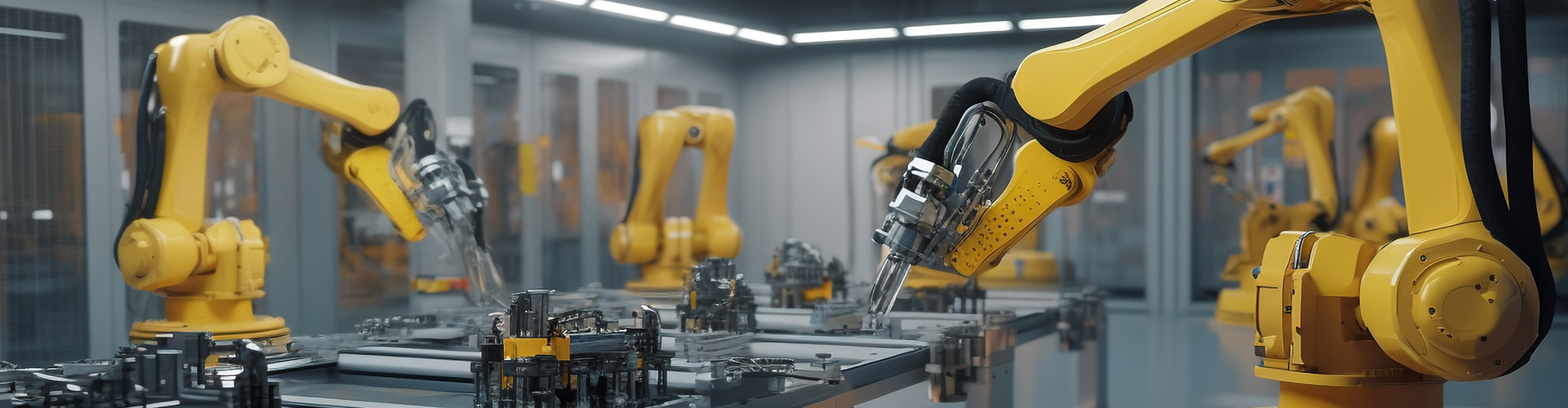

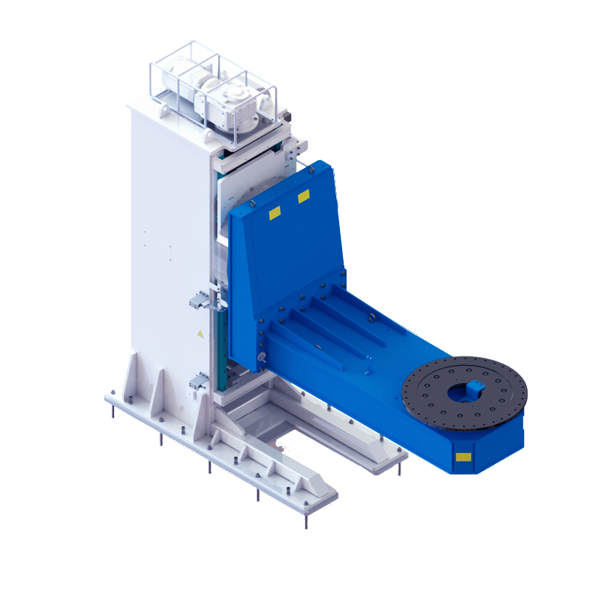

Central University Excavation (13T-55T) Bucket Arm Intelligent Welding Factory

Contact Us

Classification

Product Description

Case Introduction:

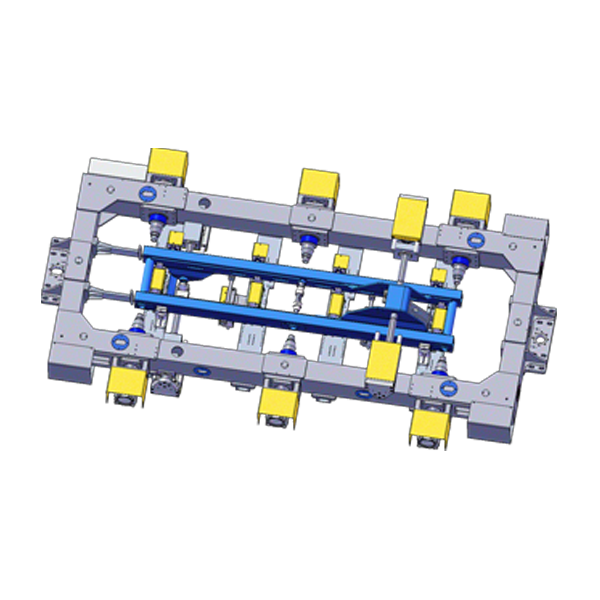

The production line consists of a boom assembly tooling unit, a boom robot welding unit, a manual boom repair welding unit, aging, and non-destructive testing units, making it a leading intelligent welding factory in the industry.

Technical Highlights:

(1) Logistics System:

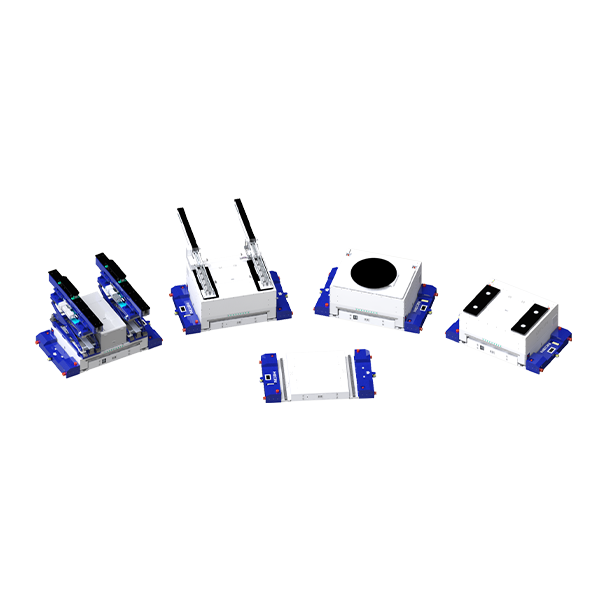

·The entire logistics system uses AGV + RGV for automatic transportation. Materials are transported from the assembly area to the manual assembly station using AGV intelligent logistics vehicles, and completed workpieces are automatically transported to the finished product buffer using RGV.

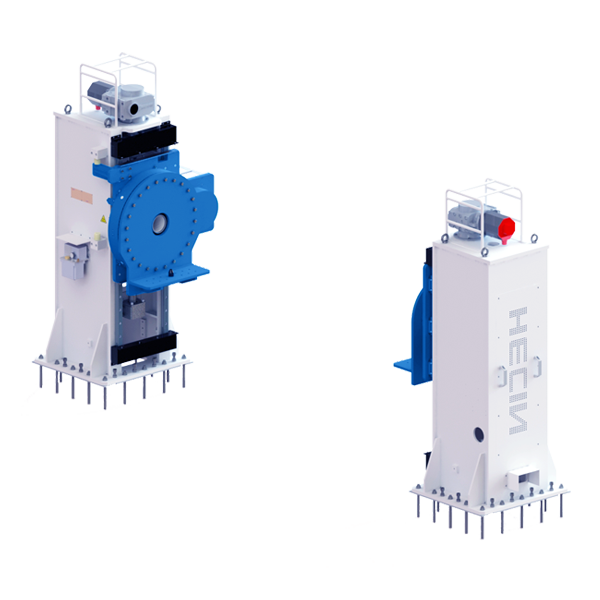

(2) The manual non-destructive testing station for the boom consists of three main parts: the material rack, UT testing equipment, and display.

(3) It uses internationally renowned welding systems. At the same time, it is compatible with the industry's first full weld 1.6mm welding wire large current welding process, which improves production efficiency by 80% compared to the traditional 1.2mm welding wire process.

(4) This production line adopts intelligent flexible centralized control, combined with an information management system, allowing for automatic program invocation for production. Additionally, it is equipped with a quality management and traceability system for the production process, as well as an intelligent safety and environmental control system, improving product quality by 70% compared to the same quality.