Excavator Core Component Digital Factory

Contact Us

Classification

Product Description

Case Introduction:

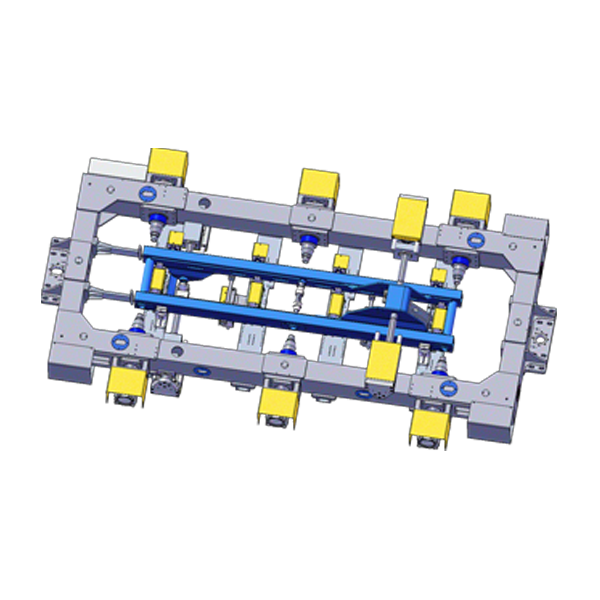

The Zhongda Excavator Core Component Intelligent Manufacturing Flexible Factory Project adopts a highly flexible intelligent manufacturing approach to produce large, medium, and small excavator booms, chassis, and small components. It introduces production processes and intelligent, information-based achievements from multiple fields, achieving comprehensive value enhancement in production, logistics, processes, quality, and management.

Technical Highlights:

·Robot vision recognition technology is widely applied in multiple environments;

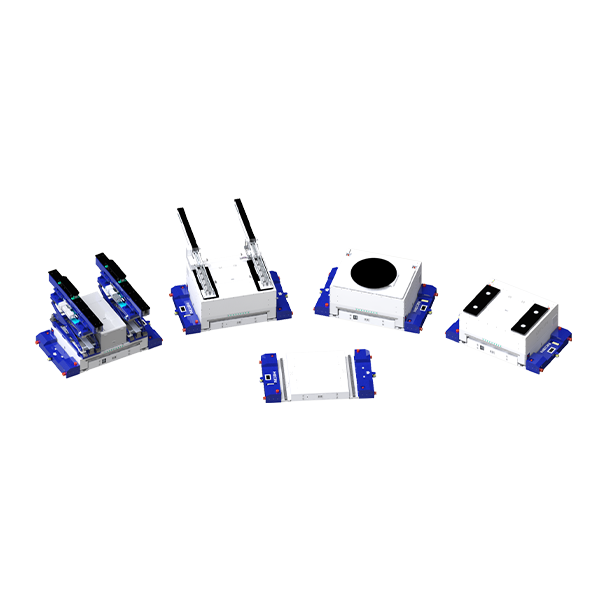

·Interaction applications under full intelligent control of AGV and RGV mother-child vehicles;

·Realization of online quality inspection of large structural components using robot UT;

·Realization of fully intelligent three-dimensional storage functions for large structural components of various specifications;

·Realization of IMS information management and SCADA online quality traceability for multiple production lines;

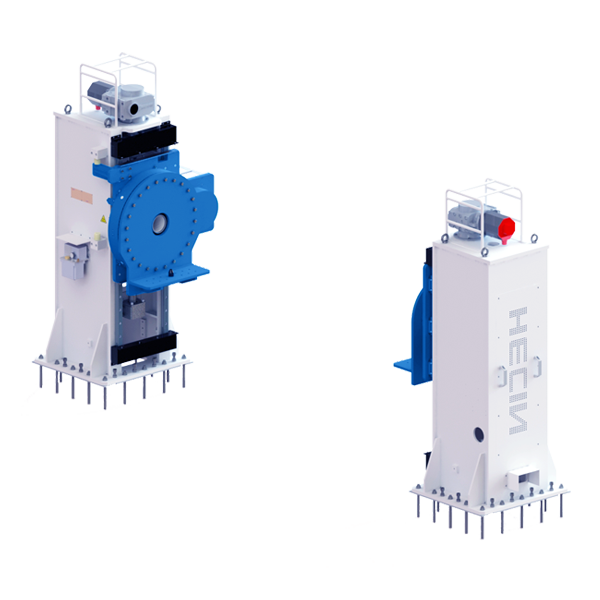

·Realization of high integration of the self-developed control system by HECIN.

·Breakthrough use of robot automatic marking technology, effectively improving marking accuracy and efficiency, suitable for various production scenarios, and seamlessly connecting and collaborating with other manufacturing processes;

·Adoption of the industry's first large-size stud welding technology, with higher welding efficiency, stronger stability, and lower costs.

This project fills the gap in intelligent manufacturing of large and medium-sized excavators in Hunan Province and has a huge promoting effect on the intelligent manufacturing industry upgrade in Changsha and the entire Hunan. It is equipped with various industrial robots and automation technologies, and the automation and intelligence level of the entire production line is very high, making it the flexible intelligent assembly production line with the highest single-unit delivery ratio in the industry.