Excavator Slewing Platform Main Body Flexible Intelligent Factory

Contact Us

Classification

Product Description

Case Introduction:

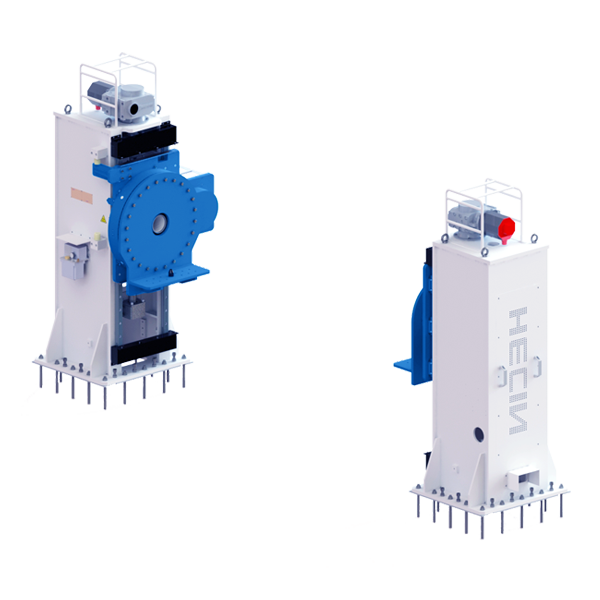

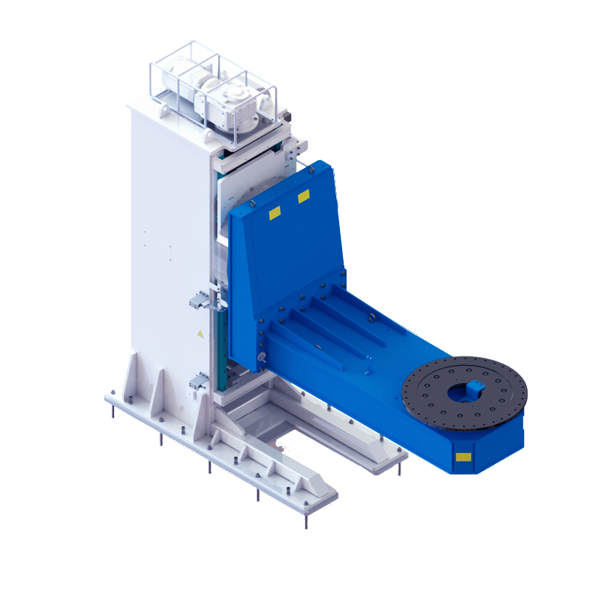

The rotary table main flexible welding line is mainly used for the welding of structural components of excavator rotary tables in the 20-40 ton range. The entire production line consists of a rotary table main robot welding station, a rotary table main repair welding station, a smoke and dust removal device, and other parts, capable of continuous automatic operation for 24 hours, with no more than 1 downtime failure in 5000 hours.

(2) Technical Highlights:

·Information visualization and transparent management, 360° production tracking without blind spots.

The overall control system enables networking and data collection of all equipment within the flexible welding line, displaying the current operating status of the production line in graphical report form. With the help of 5G and internet technology, it achieves full tracking and visualization experience of the workpiece from loading, welding, assembly to production status.

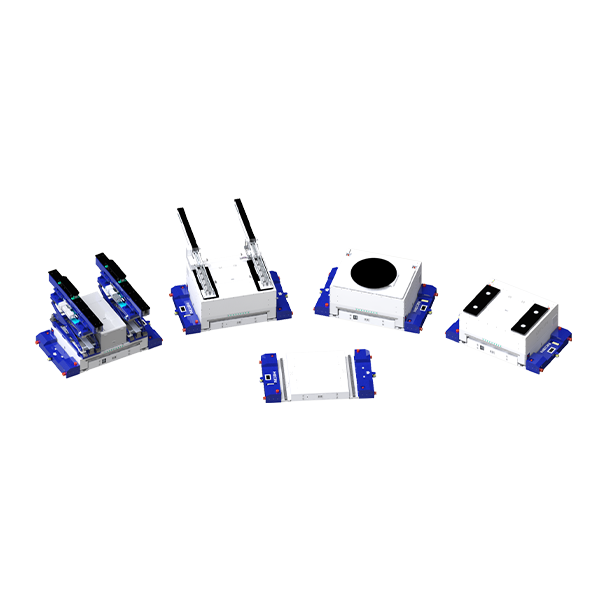

·RGV operation logistics reduce cumbersome manual handling work.

The production line is equipped with 2 RGV transport vehicles, which can automatically execute the transfer of workpieces based on order and task execution status; the welding robot station and manual repair welding station achieve automated loading and unloading of workpieces, allowing for automated operation of the flexible welding line.

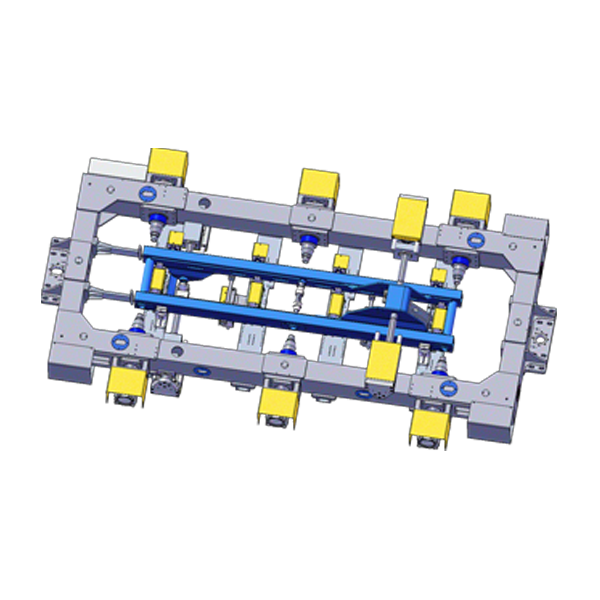

·The assembly tooling adopts a hydraulic clamping sliding table form to achieve flexible clamping within the profile.

The design of the production line adheres to principles of advanced manufacturing, green environmental protection, automated logistics, and informatization.