Automatic Splicing Intelligent Workstation for the Arm Plate of Scissor-Type Aerial Work Platform

Contact Us

Classification

Product Description

Case Introduction:

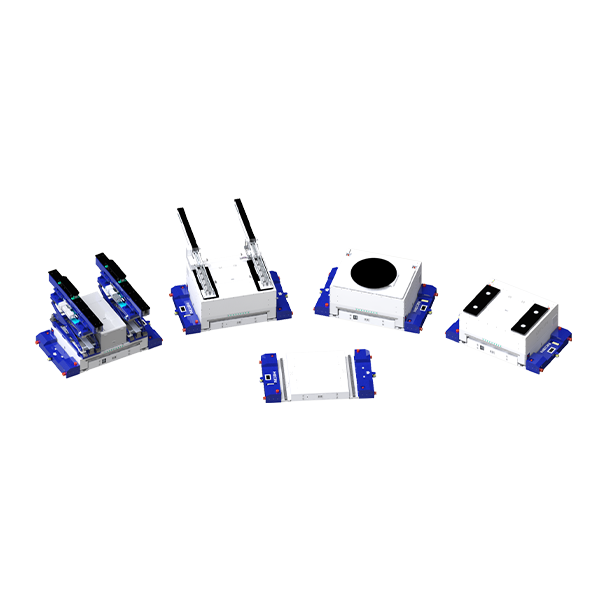

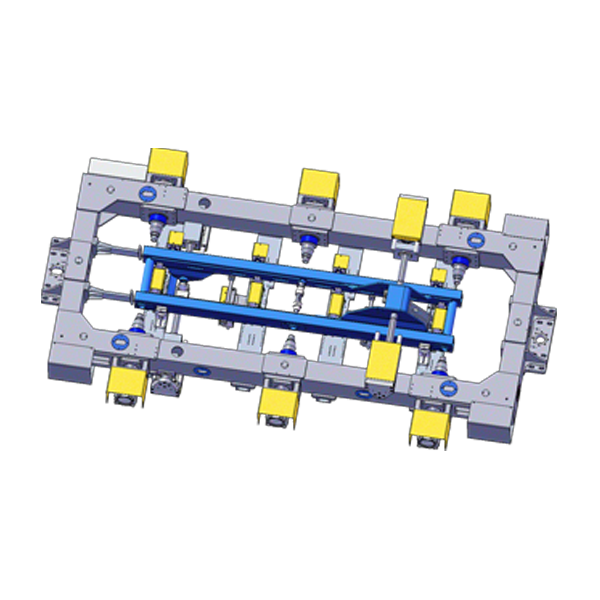

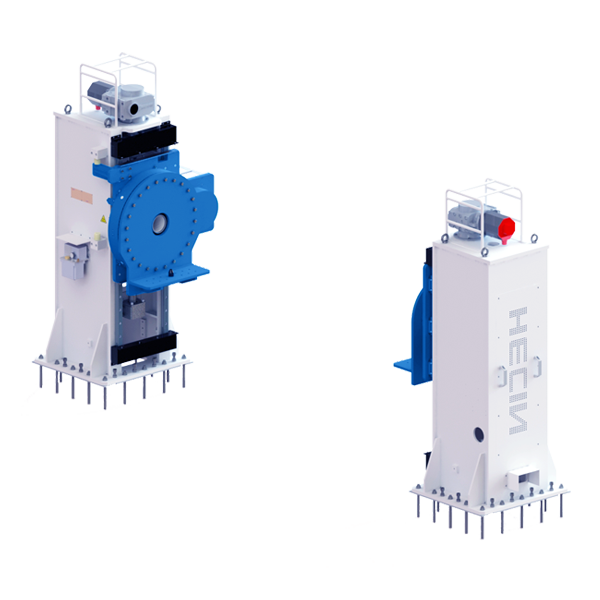

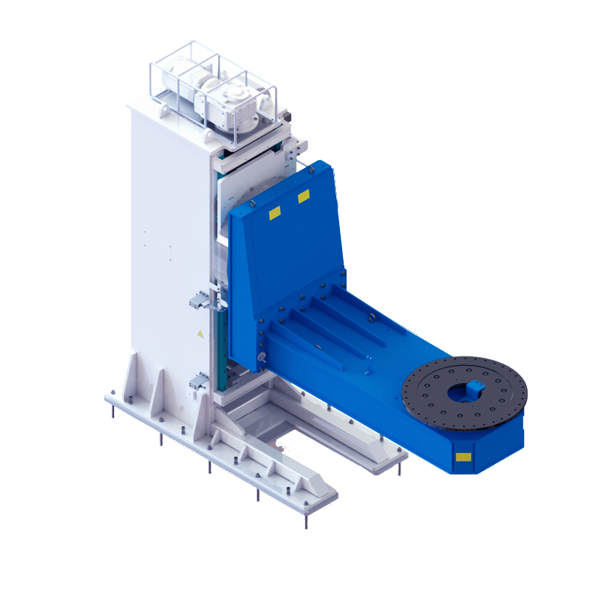

The automatic point assembly intelligent workstation for the arm frame panel is mainly used for the automatic handling, automatic clamping, and automatic point assembly of the rectangular tube of the scissor lift arm and the panel. It consists of robotic equipment, 3D visual recognition, positioning tools, panel material trays, and an information system for the production line.

Technical Highlights:

(1) Centralized control is adopted, combined with the information system of the production line to achieve real-time transmission and monitoring of welding production information.

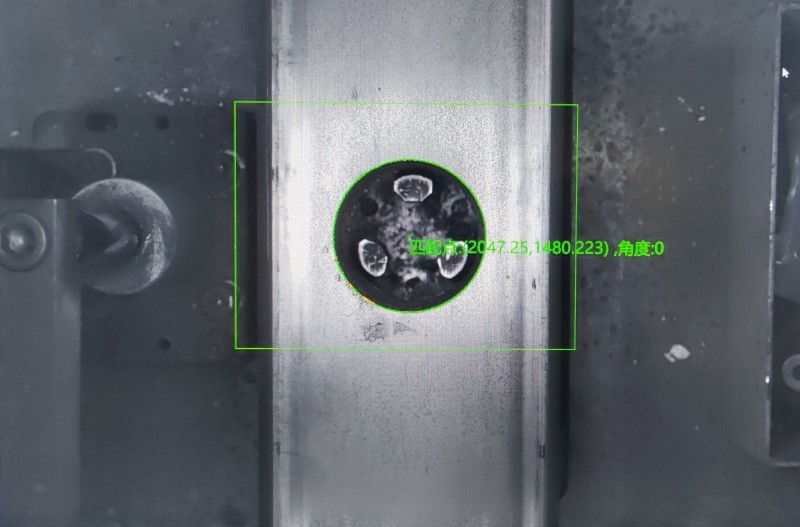

(2) Advanced 3D visual recognition technology is used to accurately identify the workpieces to be grasped.

Using 2D position correction to obtain the approximate position of incoming materials, the 3D visual sensor performs precise positioning and matching of the workpieces. This greatly reduces the positioning requirements for workpieces in the material frame, while the material frame is suitable for various types of workpieces, reducing logistics costs.

When the robot grabs the panel from the feeding point, after visual recognition, it places it on the rectangular tube, and the positioning fixture automatically clamps and welds.

The automation level of the entire work island is very high, capable of operating for 8 hours in a single shift, 3 shifts per day, and working 28 days a month.