Intelligent welding digital factory for scissor lift aerial work platforms, arms, and chassis.

Contact Us

Classification

Product Description

Case Introduction:

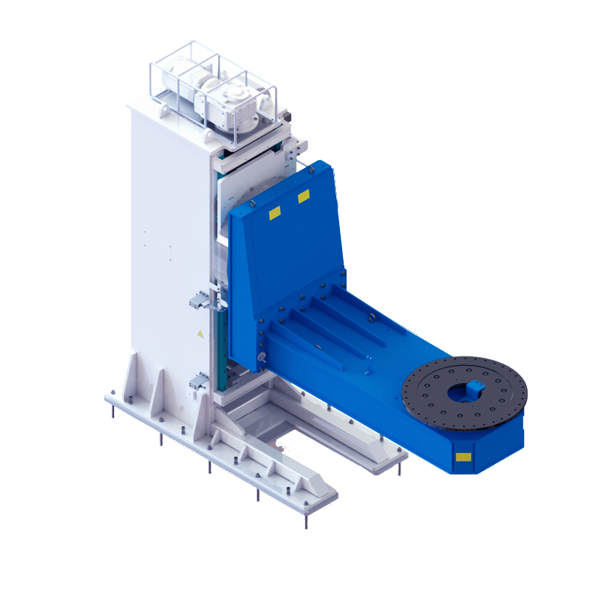

The scissor lift aerial work platform smart welding digital factory consists of an automatic loading and unloading system for the scissor lift aerial work platform, a smart welding production line for the chassis, and a smart welding production line for the arm. It undertakes the complete automatic welding production process for the components of the scissor lift aerial work platform.

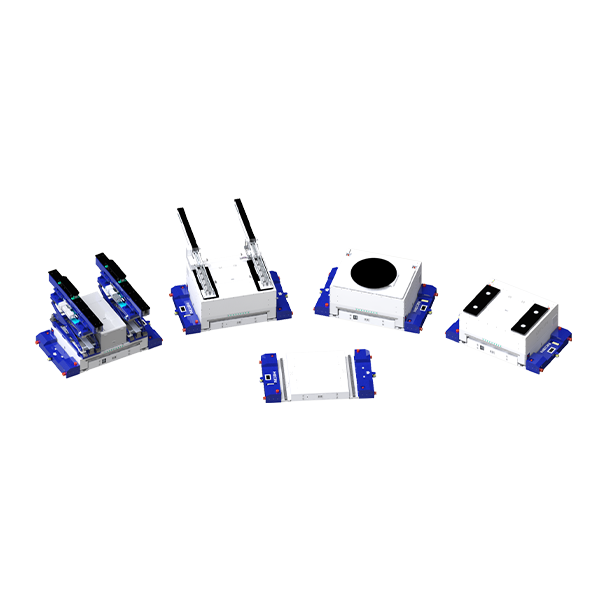

(1) Automatic loading and unloading system for the scissor lift aerial work platform:

The automatic loading and unloading system for the scissor lift aerial work platform is the front-end prefabrication process for the arm components of the scissor lift.

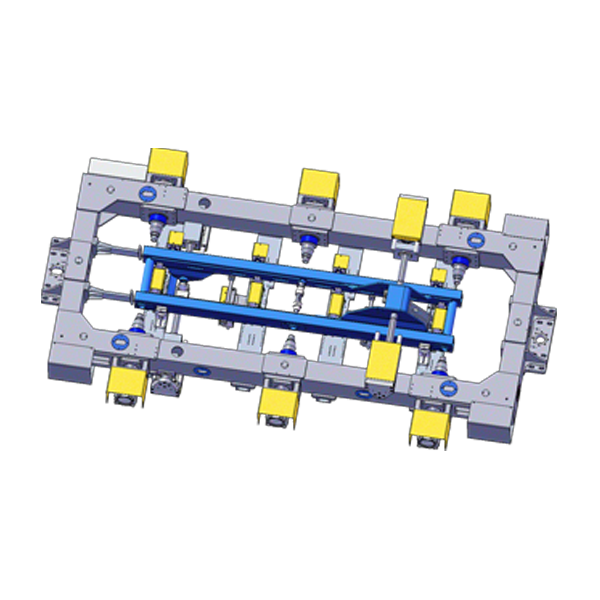

(2) Smart welding production line for the scissor lift aerial work platform arm:

This production line consists of a 6-meter scissor lift arm assembly welding line, a 10-12 meter scissor lift arm plate working station, and an intelligent logistics project for the arm welding line.

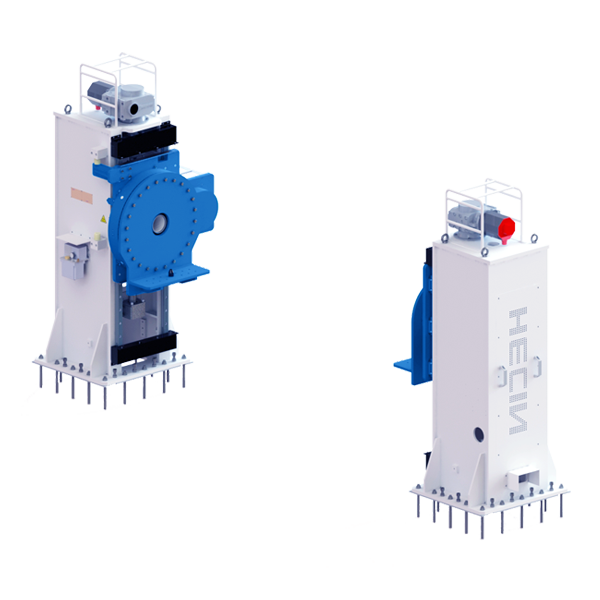

(1) Smart welding production line for the scissor lift aerial work platform chassis:

The production line consists of front and rear plate prefabrication, door box prefabrication, assembly station, total welding station, manual repair and grinding station, logistics system, dust removal system, MES system, and other components.

The automatic welding station is equipped with a follow-up dust removal system, while the repair and grinding station uses a dust removal room for centralized isolation of dust;

The MES of this line has independent management functions, controlling the production line equipment, data collection, and other functions, and requires completion of the interface connection with the company's management system, with a high degree of informatization.