Intelligent welding digital factory for structural components of scissor lift aerial work platforms.

Contact Us

Classification

Product Description

Case Introduction:

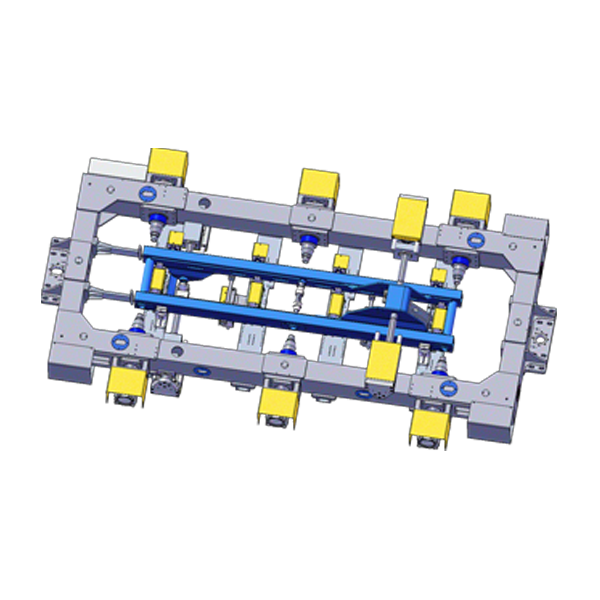

·The welding fixture of this production line can ensure the dimensional accuracy requirements after welding and guarantee the overall welding pass rate.

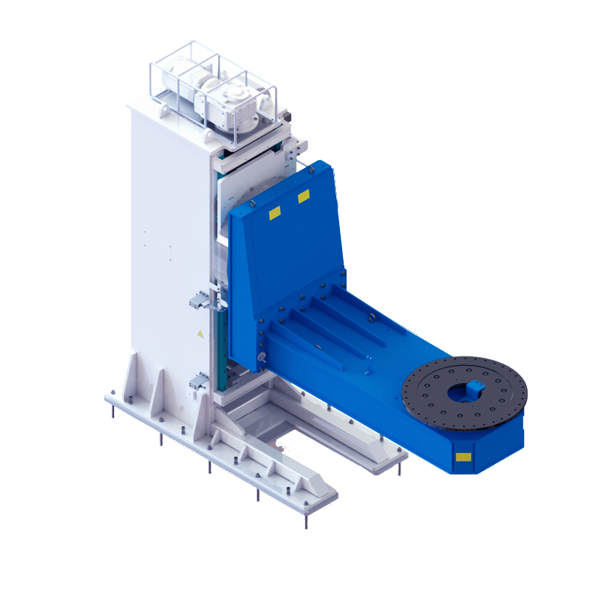

·The fixture uses hydraulic flexible clamps, which have a holding pressure function and can meet the positioning and clamping requirements of different models of square tubes at different locations, as well as reverse deformation.

·Most workstations on this production line use automatic welding, combined with advanced automatic weld seam detection technology, to achieve automation and standardization of weld seam appearance inspection, significantly reducing manual inspection errors; effectively improving the efficiency of weld quality inspection, ensuring the welding quality of workpieces, and saving costs.

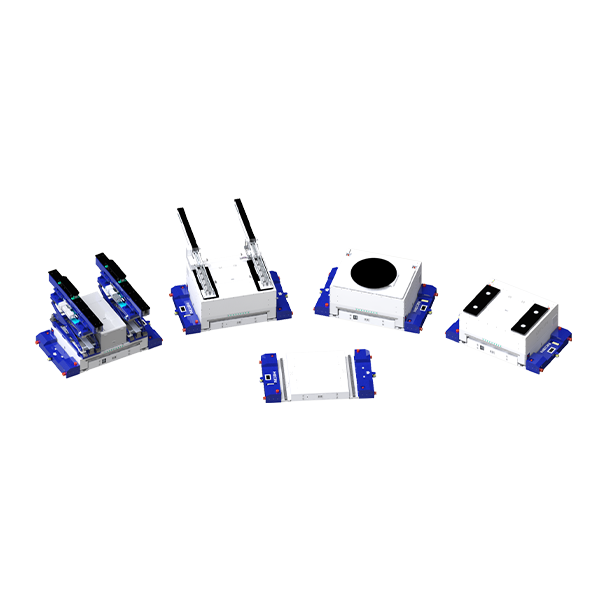

·The logistics of this production line utilize AGV trolleys for transferring and buffering workpieces, combined with high-speed chains, overhead crossings, intelligent warehouses, and other smart logistics products to achieve efficient logistics transfer.

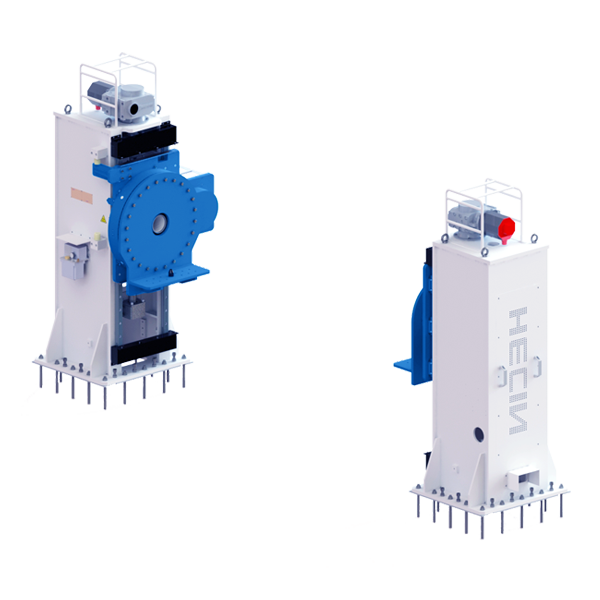

·The MES of this production line has independent management functions for controlling production line equipment, data collection, etc., and requires the completion of interface docking with the company's management system, with a high degree of informatization.