Intelligent Cutting and Digital Factory for Structural Components of Scissor Lifts

Contact Us

Classification

Product Description

Case Introduction:

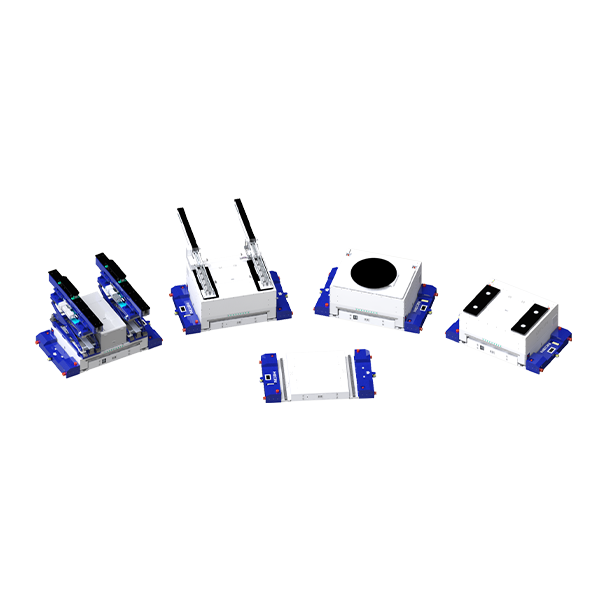

(1) The feeding line application has an advanced intelligent logistics system, which uses a warehouse management system and leverages technologies such as the Internet of Things and big data to achieve intelligent warehouse management, systematic storage management, and transparent material preparation management for enterprises with multiple goods and warehouses, refining the internal operational processes.

At the same time, by integrating intelligent vertical storage, robotic arms, and AGV intelligent logistics scheduling systems, it realizes intelligent cloud-based material logistics in the workshop, enhancing inventory turnover efficiency, improving inventory accuracy, optimizing warehouse operation standards, and creating real-time, transparent, and visual warehouse logistics management.

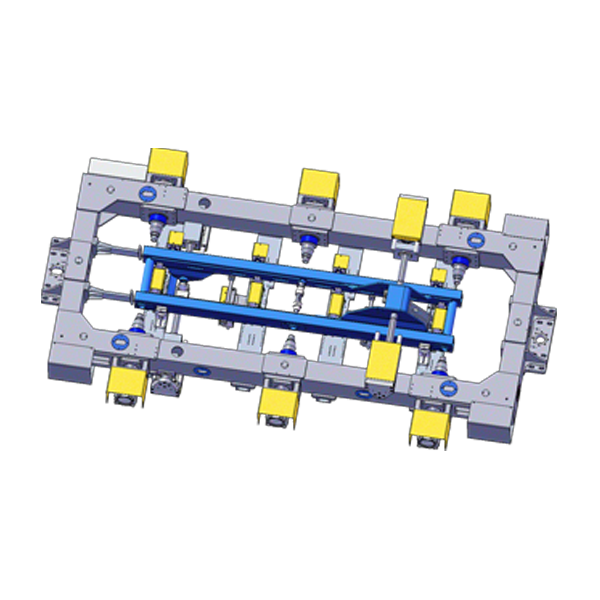

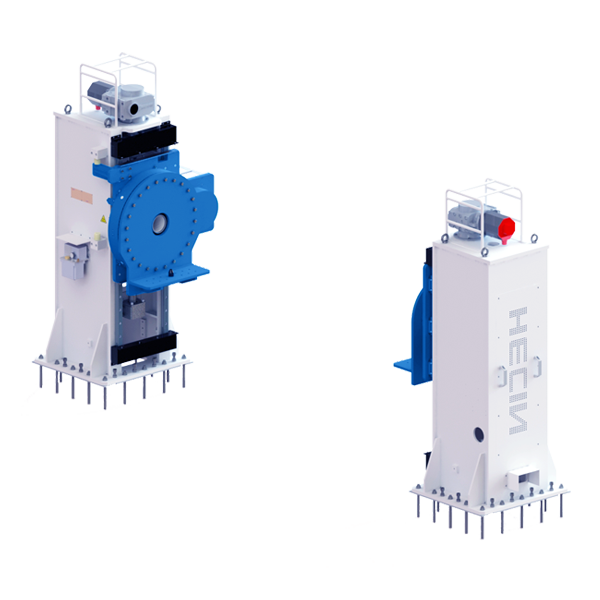

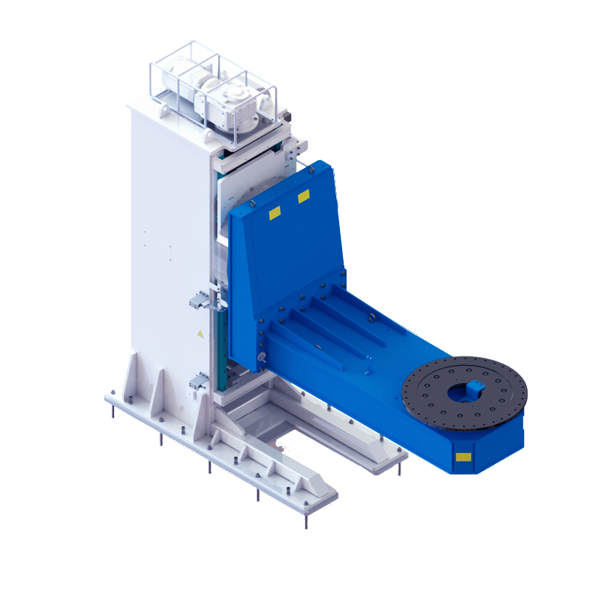

(2) Due to the large burrs from cutting rectangular pipes and the excessive cutting debris in the inner cavity, manual processing is difficult. To address industry pain points, the production line employs a fully automatic grinding system to grind the inner cavity and outer cross-section of rectangular pipes, significantly improving workpiece quality and reducing manual labor intensity.

The entire production line is highly informationized, intelligent, and automated, achieving unmanned management; while helping customers save labor costs and realize capacity leaps, it greatly enhances production stability and safety.